CATEGORY

SINGLE SIDED DIAPHRAGM COATING MACHINE

Tel:

产品规格:

零售价

市场价

隐藏域元素占位

Details

Equipment Introduction

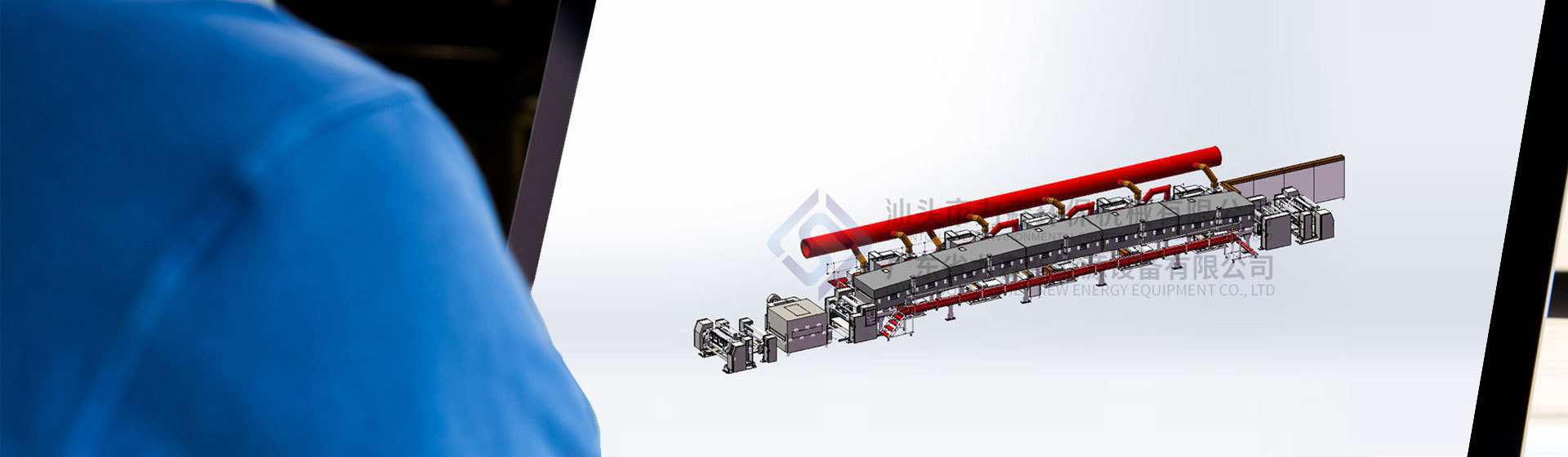

The single-sided water-based membrane coating machine is composed of a unwinding unit, a preheating unit, a traction coating unit, an electric heating hot air oven drying unit, a shaping cooling unit, a winding unit, and an electronic control system; Apply the stirred slurry evenly on the substrate, ensuring that the size, weight, etc. are within the design specifications. After drying and shaping treatment, roll it up to prepare for the subsequent process. This machine is suitable for evenly coating water-based coatings on electronic diaphragm layers. This machine integrates light, machinery, and electricity, and is carefully designed, manufactured, and assembled. It has uniform coating, neat winding surface, stable running tension, and convenient operation, making it an ideal water-based coating equipment for diaphragms.

Characteristic DescriptionThe control adopts COTRUST PLC, with stable operation and user-friendly operation;

The unwinding and rewinding are automatically changed at two workstations, saving time and improving efficiency

The unwinding and correction system adopts a universal source ultrasonic correction system, which is sensitive in action and has high accuracy;

The winding correction adopts a universal source ultrasonic belt misalignment function correction system, which is sensitive in action and has high accuracy;

The winding meter can be stored multiple times and historical records can be displayed;

The coating is sealed scraper kiss coating, with controllable accuracy and uniform adhesive application

Traction vacuum roller traction reduces film scratches and improves product quality

The guide roller of the oven adopts a fully active transmission to overcome tension fluctuations caused by membrane thermal deformation

Winding gap type follow-up pressure roller ensures stable winding tension

The mechanical design, processing, and assembly standards of the entire machine are unified, and the wall panels are processed in pairs. After annealing treatment, they are bored and milled multiple times in the machining center, ensuring the precision of the entire machine

Technical Parameter

|

Applicable coating substrate |

PE/PP/battery separator Thickness: 5-25μm |

|

Coating layer thickness |

1.0-4.0μm |

|

Guaranteed Coating Width |

400mm-1300mm (can be customized according to actual situation) |

|

Coating method |

Continuous transfer one-sided kiss coating method |

|

Shrink ratio |

When the thickness of the original PP film is 12um and the width is 1000mm, the shrinkage of the finished product is less than 2mm |

|

Mechanical Speed |

300m/min |

|

Coating working speed |

20-200 m/min (depending on process and material) |

|

Guide roller web width |

1400mm (can be customized according to actual situation) |

|

Material Diameter |

Unwinding Maxφ500mm, rewinding Maxφ500mm, (can be customized according to actual situation) |

|

Unwinding and rewinding mandrel size |

Using the cone-top reel fixing method, the 6-inch\8-inch reel can be switched by replacing the cone-top, and the core width is Max.1400mm. |

|

Guide roller surface treatment |

A aluminum roller: surface hard oxidation HV700, mirror finish B steel roller: hard chrome plated mirror finish |

|

Coil Weight |

Max.100kg |

|

The uniformity of winding section |

Misaligned winding end face≤5mm |

|

Tension Control Accuracy |

Tension range of the whole machine: 0-100N/full width, precision±2N |

|

Heating Oven |

The total length is 20 meters, 4 meters per section, blowing up and down, independent temperature control for each section, frequency conversion control of the fan |

|

Heating method |

Electric oven heating (can be customized according to actual situation) |

|

Oven temperature |

The outer temperature of the oven is < room temperature + 20°C (except for the connection port), the maximum wind speed is 12 m/s, the maximum temperature is 120°C, and the accuracy is ±1°C |

key word:

High speed lithium battery separator coating machine/lithium battery separator cutting machine/lithium battery separator modification machine

Related products

Messages