09

2022

-

12

Xinruichino: APE membrane is here, a blue ocean market that cannot be underestimated!

Li Xuecheng, General Manager of Shantou Lishen Environmental Protection Machinery Co., Ltd., has conducted in-depth technical discussions and tests on the performance of PVA coatings and PE substrates, as well as tension control of equipment, production process, oven design, and other aspects. Lishen Machinery Mr. Li is also an expert with over 20 years of experience in coating machinery design and manufacturing, and a deep understanding of coating technology. The two senior experts have formed a strong alliance, and after more than a year of diligent research and repeated testing, Finally, a customized coating machine suitable for APE was made.

Coating plant

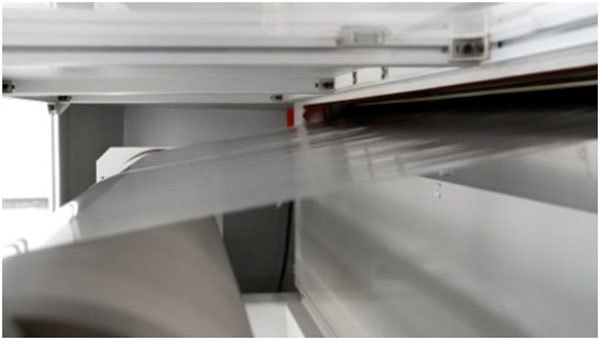

The ultra long oven is located on the second floor (there is a contradiction between high-temperature coating and PE's inability to withstand high temperatures. Shantou Lishen coating equipment perfectly solves this problem by controlling the tension in the high-temperature area)

Li Xuecheng, General Manager of Shantou Lishen Environmental Protection Machinery Co., Ltd., introduced the unique features of coating equipment

Overall, the production of APE membranes needs to focus on three major aspects:

The equipment should control the stretching of the film to ensure that it does not stretch or deform after coating;

The substrate formula needs to be communicated and coordinated with the PE film factory, requiring the other party to make subtle personalized adjustments to the PE film according to the coating requirements;

We also need to do a good job in cost control.

In October 2021, this customized coating equipment began mass production at the Xinruichino factory, and the APE coating film officially began market application in early May this year. The equipment is currently operating at a speed of 400m/min for 24 hours without stopping production, with a production capacity of 20 tons per day and around 600 tons per month.

At present, the application of APE is still in the embryonic market, but its recyclability and barrier properties are excellent, which can meet multiple performance requirements such as printing adaptability, barrier properties, and heat sealing bag making for single PE material packaging. With the continuous development of materials and processes, it is estimated that it will usher in a blowout in the next 3-5 years. At that time, the well-established Xinruiqino has mature APE production experience, and its products and production capacity can fully meet market demand.

3、 APE usage precautions and application issues

APE is similar to nylon in some aspects and also has water absorption. Therefore, during use, the protection requirements are relatively high, and the production process is close to nylon. If it is applied on the printing layer, it is not suitable to use water ink printing or water glue composite; If using ink or glue, it is recommended to apply it to the bottom film. When PVA is applied to the bottom film PE, the barrier properties of APE/PE can be improved dozens of times compared to nylon/PE. In addition, because PVA has water absorption, this type of material is not suitable for products such as water boiling and steaming.

PVA high barrier coating film is a new material in the industry, and Mr. Yang believes that there will definitely be many new problems in its application.

1. Requirements for material peel strength, barrier properties, etc. need to be redefined

Especially for single material structures, taking APE/PE as an example, its strength has definitely changed compared to PE/PE. So, on the basis of meeting the packaging, storage, and transportation requirements, how much does APE/PE need to achieve in terms of peel strength, barrier properties, and heat shrinkage to be considered qualified? How is its drop resistance defined?

2. Testing tools and methods need to be updated

At present, Dongfeng Group has reached a cooperation with a research institute in Canada, hoping to make breakthroughs in testing tools and technology. It also hopes that the industry can introduce corresponding standards to better safeguard production!

4、 ConclusionAPE film has arrived and has been favored by a domestic dairy giant, perfectly used for sterile milk packaging. Because the coating is thin and has excellent oxygen resistance, it provides strong technical support for expanding the application field of single PE material recyclable packaging! Mr. Yang is confident in the future market application prospects of APE film, and the only biggest problem currently troubling him is the insufficient supply of PE film substrates suitable for PVA coating. However, with the expansion of market applications and the continuous improvement of materials and process technology, it is believed that this dilemma will soon be broken.

The most challenging APE coating film has been successfully developed by General Manager Yang Weihong with the joint efforts of equipment and material suppliers, as well as a technical team of over 20 people from Xinruiqino. It is an innovative and environmentally friendly material that fills the gap in China and is a leading technology even in the international market. It embodies the research efforts of Mr. Yang in coating technology for over 20 years, and all his efforts and efforts have finally yielded fruitful results, which makes Mr. Yang feel proud and gratified.

The market never disappoints good products! APE, worthy of attention; As the leader of the enterprise, General Manager Yang Weihong, a technical controller who is fearless of difficulties, brave in challenges, skilled in thinking, and resilient, and a pioneer who strives and strives tirelessly with ideals, under his leadership, Xinruichino will surely usher in a more brilliant and brilliant tomorrow!